Intro

Ensuring impeccable quality is a top priority for any food and beverage production line. Maintaining the highest standards strengthens brand reputation, protects against recalls, and safeguards against costly defects and damages. FILTEC's Intellect Inspection Platform uses advanced cutting-edge photon and machine vision technologies to offer a comprehensive quality assurance solution that significantly elevates your production line. Let's explore the benefits your line will receive by integrating the Intellect Inspection Platform.

- Early Detection of Negative Trends

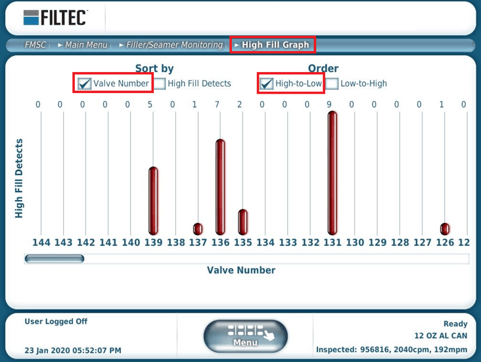

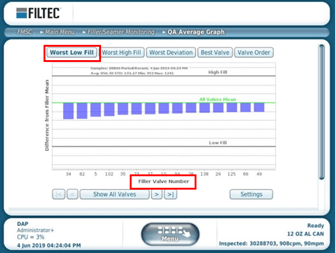

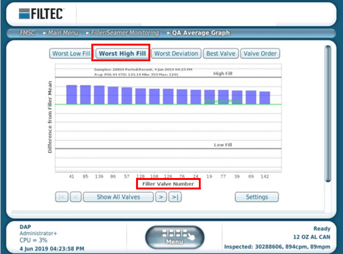

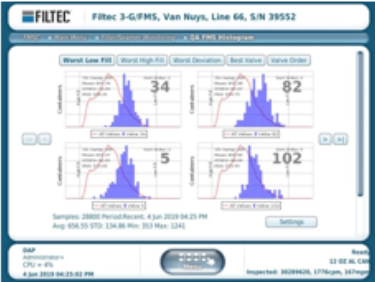

Intellect monitors every filling cycle and meticulously tracks even minor deviations in fill levels, trending an unacceptable performance. This allows the platform to provide you with early warning signals of negative trends, such as increased under- or overfilling in the fill cycle. With this information at your fingertips, you can pinpoint problematic valves, understand the root cause, and take corrective action before the valve fails to meet the required filling standards.

2. Preventative Maintenance

A major reason for over and underfilled products is poorly performing filler valves. By adding Intellect’s early detection capabilities, you can proactively perform preventative maintenance before the valve causes you to have unsellable products. Interventions to resolve the root cause of a trend are typically simpler and less labor-intensive, requiring only the repair of a valve component or a cleaning procedure. By adding preventative maintenance measures, you can improve the line efficiency and maximize throughput capacity. Moreover, the maintenance team can focus on valves that genuinely require attention, rather than following a pre-set service schedule.

3. Real-time Data Insights

With Intellect, you gain a real-time understanding of valve performance trends. The system provides you with data points that feed dashboards with trends and statistical calculations over time, making it easy to inspect data for individual valves in your production line. The data gives a new level of process transparency previously unavailable before. Thus, you can efficiently monitor valve performance and intervene proactively to maintain desired fill levels.

4. Comprehensive Solutions for Your Filling Lines

FILTEC's Intellect inspection platform is a modular solution that integrates with dedicated inspection solutions, such as label, cap and closure, and pressure/DUD detection. By adding quantitative analysis and automated photon and machine vision inspection technologies, you are ensuring that your line will continue to modernize, scale, and automate inspection in the future.

Conclusion

Incorporating FILTEC's Intellect inspection technology into your production line provides you with the necessary tools to accurately monitor and report on valve performances. By leveraging Intellect's intelligent algorithms, you gain visibility into fill-level trends, detect negative trends early, and perform preventative maintenance ensuring maximum line efficiencies. Moreover, the platform's comprehensive solution approach enables you to protect products' quality and safeguard your brand's reputation, all while taking advantage of Intellect’s scalable, future-proof approach to inspection.

Bring next-generation intelligence to your production lines with FILTEC's Intellect inspection platform. Contact us today to learn more about how our innovative solution can revolutionize your quality assurance and performance optimization processes. https://www.filtec.com/products/intellect/

(888) 434-5832

(888) 434-5832