Plastic bottles have become common sights at grocery and convenience stores. In fact, over the past couple of decades, the growth in plastic has been so dramatic you might think that eventually, plastic will completely replace aluminum beverage cans. However, recent data has uncovered that aluminum is making a comeback, and plastic bottles may actually completely disappear from store shelves.

Why the Shift to Aluminum?

There are several reasons for this switch from plastic to aluminum, but the primary motivator can be summarized with a single word: sustainability. Aluminum is one of the only packaging materials that 100% recyclable. This means that an aluminum beverage can have a 100% chance of being recycled back into a beverage can after use. It is this ability to be recycled indefinitely that lends itself to sustainability efforts. In fact, it has been estimated that approximately 75% of all aluminum ever produced in the United States is still in use today.

How FILTEC is here to Help Your Move into a Sustainable Future

FILTEC supports sustainability by giving manufacturers the inspection equipment needed to ensure the on your production line are clean, free of damages, and safe for consumers.

The FILTEC Empty Can Inspection Solution is a highly configurable system that uses Vision technology to detect defects in empty cans. This solution:

- Is equipped with modern Vision inspection technology

- Has a compact machine footprint

- Easily integrates with existing production lines

- Reduces jams at the filler and seamer

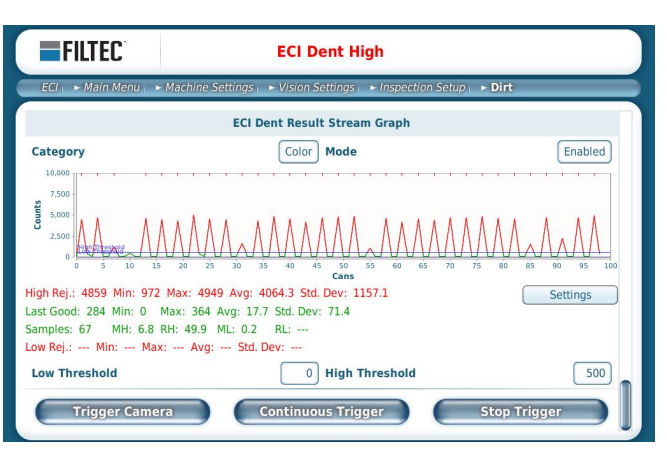

- Offers continuous monitoring and statistical analysis of container integrity

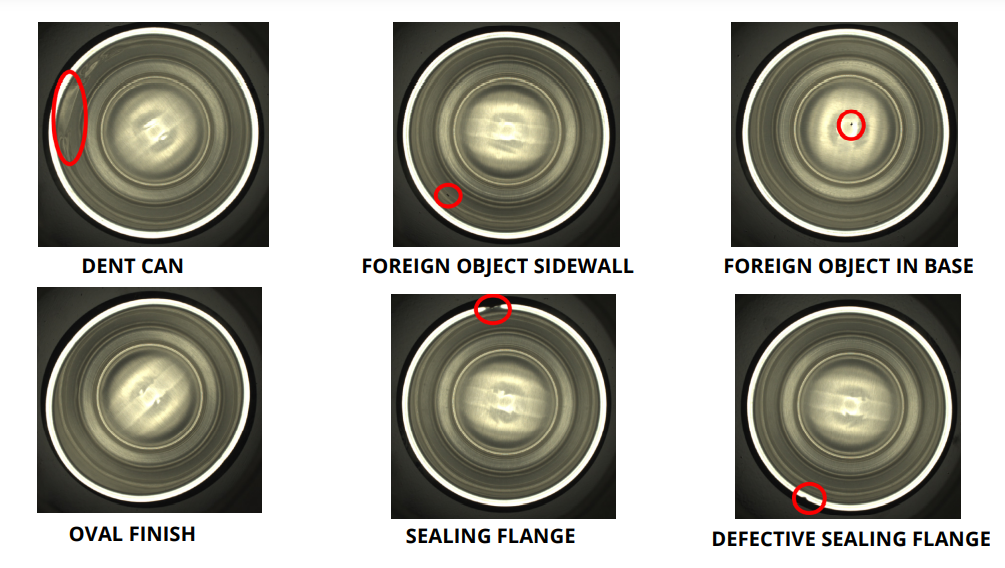

The FILTEC Empty Can inspection system inspects the most common defects in cans: Inner Sidewalls, Base, and Sealing Flange. It also inspects for foreign objects.

By inspecting the cans for damages or contamination before they are filled, you are helping to avoid serious downstream leakages or jams. And because the FILTEC Empty Can Inspection system integrates with the INTELLECT platform, empty can data is analyzed and checked against threshold reject limits set by the operators and used to assure the quality of each container. INTELLECT pinpoints dents, dirt, oil, bends, and broken cans, and removes them from the line before they are filled – saving you significant time and money traditionally spent on rejects and product waste. Even better, FILTEC’s Empty Can Inspection solution seamlessly integrates with other INTELLECT modules, so that you can have end-to-end inspection solutions on your line.

In closing, the use of aluminum is a sustainable and economical alternative to plastic for food and beverage containers. To ensure that aluminum containers make their way to the point of sale without damage or danger to the consumer, quality assurance inspection should be a top priority.

To learn more about FILTEC’s Empty Can Inspection solution and see a video of the machine in action, visit: https://www.filtec.com/products/empty-can/vision-empty-can-inspection/

(888) 434-5832

(888) 434-5832 (888) 434-5832

(888) 434-5832