(888) 434-5832

(888) 434-5832

Intro

Many beer, wine, and beverage producers struggle with low and over-fill bottles and cans; especially when sending those defective products out to customers can lower your overall ROI and increase customer complaints. Providing cans and bottles with the exact amounts of product needed requires precision tools and processes. Adding a Filler Management System (FMS) to your bottling or canning line examines and monitors filler and capper performance during production, assuring that the right amount of liquid is in each container before it's sealed.

What should the ideal Filler Management System do?

The ideal Filler Management system should be positioned before the seamer for an incredibly accurate fill level and valve performance measurement. It should also be able to sample the filler and/or capper valves at high production speeds, and accurately pinpoint poorly performing filler valves and capper heads in real-time. Lastly, an ideal system makes the job of the plant maintenance manager easier because they are now able to focus on fixing the problem valves and capper heads during maintenance leaks.

How FILTEC is here to Help Your Filler Valves and Capper Heads

FILTEC is there to support manufacturers by providing the necessary inspection equipment needed to accurately monitor and analyze each filler valve to provide a complete statistical analysis of the entire filler.

FILTEC offers a range of photon and vision Filler Management Systems to fit almost any bottle or canning line. The solutions use machine vision or photons to measure fill levels in glass and clear plastic bottles on lines operating up to 1,200 bottles per minute (BPM). FILTEC's Filler Management System is customizable to fit your specific inspection needs which is why it uses Vision or Photon technologies for the most accurate filler management based on the container and product. Our FMS system samples filler valves and closer or capper heads at high production speeds; as well as isolating individual valves and closer or capper heads to analyze performance.

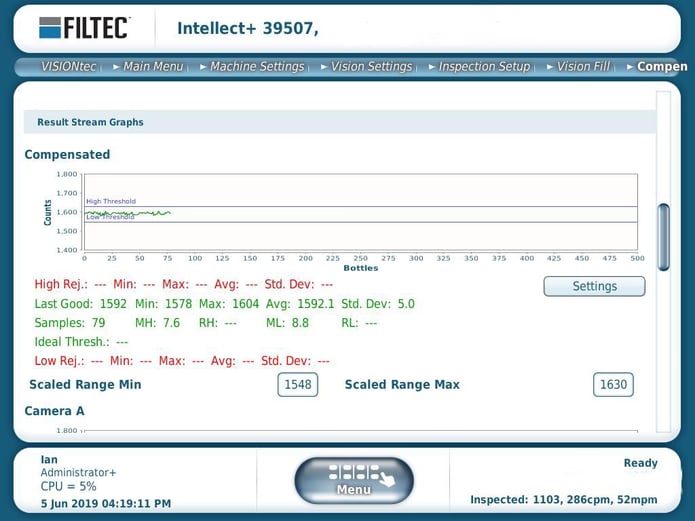

By inspecting the bottles and cans for gross underfill and overfill, you are helping to maintain the integrity of your product and only sending the perfect bottles and cans to the next stage down the production line. And because the FILTEC Filler Management system integrates with the INTELLECT platform, you will have a deeper view of your line data. By integrating the INTELLECT Platform, you will have access to features such as continuous monitoring and statistical analysis of line operations and filler valve and closer or capper head sampling. INTELLECT isolates and evaluates the performance of individual filler valves and closer or capper heads to pinpoint which valve and closer or capper are causing gross underfill or overfill– saving you significant time and money traditionally spent on rejects and product waste. Even better, FILTEC's Filler Management System solution seamlessly integrates with other INTELLECT modules, so that you can have end-to-end inspection solutions on your line.

Review valve and line health in real-time with FILTEC Filler Management Systems

In closing, FILTEC's Filler Management System helps ensure the overall line health of thousands of beverage producers. When coupled with FILTEC's INTELLECT Smart Inspection Platform, FILTEC can provide beverage producers with the peace of mind of accurate and precise inspection. To ensure that every bottle can make its way to the point of sale with the correct fill level, quality assurance inspection should be a top priority.

To learn more about FILTEC's Filler Management System visit: https://www.filtec.com/products/full-bottle/filler-management-system-for-bottles/

In beverage and liquid products manufacturing, precision is...

Call us today! (888) 434-5832

Request a Quote