Adding fill level inspection, empty container inspection, closure and sealer, or other inspection technologies to your food, beverage, pharmaceutical, or consumer goods lines is a great way to ensure your products remain safe through all stages of production. They also help avoid expensive overfill costs or the damages that imperfections to your products or containers can have on your brand. (Think, “How did that old wrapper make its way into my soda bottle?” – a question your customers should never have to ask!)

But it’s possible to take this quality assurance to the next level thanks to new technologies, including machine vision cameras, the ability to track containers though the entire inspection process, and analysis software that detects, measures and tracks defects along the way. This is where adding intelligence to your production line comes in.

Key components of “smart” inspection platform should include:

- An intuitive user interface: An intuitive UI is incredibly important, especially when measuring many different types of quality assurance – including the amount of fill, the pressure of the container, the position of product labels, and if cases are securely glued shut. The ideal user interface should be large enough to easily read and feature a touch screen menu that enables you to navigate the platform quickly and easily.

- The ability to measure many types of inspection: The ideal inspection platform should incorporate many different types of inspection techniques, including Vision, Photon, and Thermal sensors. A “smart” platform should also support many different inspection applications on a single line. This could include fill level, cap and closure, pressure, label, and, at the packer, inspection to make sure cases contain the correct amount of product and hot melt adhesive is applied adequately.

- Connectivity: When selecting a smart inspection platform, a key component is seamless connectivity and integration. This includes I/O or data links like OPC-UA and Modbus as needed for proper operation and connectivity to the production line. It also includes the ability for operators to remotely access data as needed – which can be especially important through a global pandemic.

- Scalability: Ideally, an inspection platform should support the addition of new modules over time – i.e. adding empty bottle inspection or cap and closure/pressure inspection to your fill level capabilities. Any of these inspection modules should be easily integrated into an existing system at any time so that your system can grow as your inspection needs and quality requirements change.

- Intelligence: Finally, the ideal inspection system should be intelligent. This means using sophisticated analytical methods to monitor production throughout the line, including the effectiveness of equipment (think “filler valve output”) as well as the state of production (think “individual can or bottle fill level”). The perfect solution should be equipped with a proper set of sensors and connections to the process equipment in order to trace each container back to the stage in the production process where the defect occurred. For instance, an underfilled container can be traced back to the valve or dented closure can be traced back to the crowner head.

We’ve covered five characteristics of an ideal smart inspection platform, and you may be familiar with solutions that cover some of these key characteristics, but not others. One platform that has all five of these attributes is FILTEC’s INTELLECT platform. INTELLECT integrates a user-friendly interface with incredibly accurate tracking through multiple types of inspection. Its Intelligent Analytics Software makes it possible to pinpoint the source of a problem and statistically monitor each production process step.

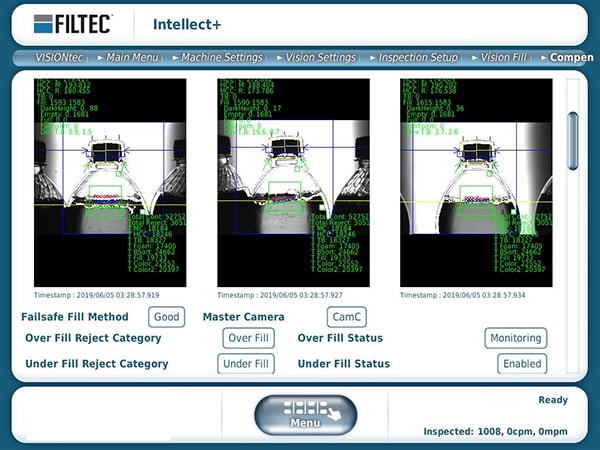

The FILTEC INTELLECT User Interface for Fill Level Management

The FILTEC INTELLECT User Interface for Fill Level Management

INTELLECT’s interface provides tools to view the results of this analysis, and its data connectivity transfers the inspection of analysis information into the production line quality control system.

You can learn more by watching this video, and you can contact our team to find out if INTELLECT is the right fit for your production line!

(888) 434-5832

(888) 434-5832 The FILTEC INTELLECT User Interface for Fill Level Management

The FILTEC INTELLECT User Interface for Fill Level Management