FILTEC: So Much More than Fill Level Inspection

Intro

You know FILTEC is a leading manufacturer of solutions for Fill Level Inspection, but did you know that we also provide solutions for empty cans and empty bottle inspections? If you are looking for a solution to inspect empty cans or empty PET or glass bottles for defects and foreign objects, FILTEC has the perfect solution for your line!

The Next Evolution of Empty Bottle Inspection: Meet the Omnivision 4 with Intellect

The FILTEC OMNIVISION 4 with INTELLECT (OV4) combines the benefits of current empty bottle inspection technologies with FILTEC´s unique INTELLECT platform, providing best-in-class inspection performance and user-friendly operation. This solution for empty bottles performs a thorough inspection of every surface of every container and rejects imperfect bottles before they have a chance to reach the filler. This all-surface pre-wash solution is able to accurately detect foreign objects and flaws in the base, sidewall, finish, and threads of empty transparent containers. With processing speeds of up to 1,400 bottles per minute, FILTEC’s Omnivision 4 with Intellect has the fastest image processing technology on the market.

Major Beverage producer enjoys the ease of an automated and precise inspection, knowing that every bottle will be checked for defects and contaminants, such as mold or trash inside the bottle, in which case the bottle will be rejected off the line. “Before FILTEC, we inspected the bottles manually which took a lot of time and slowed the overall inspection process down. Now that we have moved to a more automated system, not only have we improved the inspection quality, but we have also been able to speed up the process by 50%,” explains Kevin Briton, Maintenance Manager.

Empty Can Inspection

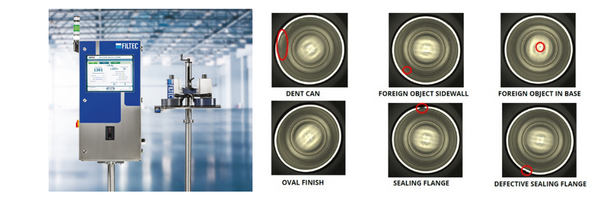

The Filtec Empty Can Inspection Solution is a highly configurable system that uses Vision technology to detect defects in empty cans on lines running up to 2,400 cans per minute (CPM). It uses a dual circular top lighting station that illuminates the inspection area for inspection of empty cans’ flange, surface, and bottom. This solution system is equipped with modern Vision inspection technology, and a compact machine footprint, it easily integrates with existing production lines, reduces jams at the filler and seamer, and offers continuous monitoring and statistical analysis of container integrity. Before aluminum cans reach the filler, they can easily suffer damage to Inner Sidewalls, Base, and Rims.

EVERYTHING UNIQUELY POWERED BY INTELLECT

FILTEC INTELLECT is a unique container inspection platform designed to track, monitor, and report on container quality through each step of the entire packaging process. INTELLECT provides a user-friendly 19″ color touch screen operator interface. The platform integrates multiple types of inspection technologies in a modular fashion to reduce size-of-footprint on the line.

Learn more about Intelligent Inspection with INTELLECT

(888) 434-5832

(888) 434-5832 (888) 434-5832

(888) 434-5832