Thank you to everyone who joined us at this year’s BrauBeviale held in Nuremberg, Germany. We are grateful for the overwhelming response and the opportunity to showcase our cutting-edge solutions. We were delighted to have visitors from 26 different countries at our stand, truly reflecting the global reach of our products.

The strong interest in our Omnivision 4, which has received approval from industry giants like Coca-Cola and other beverage groups, was a clear highlight of the show. Another standout was our Tethered Cap Inspection System which our team was thrilled to demonstrate.

Joining us at the 2024 BrauBeviale convention was our Kestrel Vision Group partner, Pressco. The partnership with Pressco enables us to offer complete inspection solutions for PET, Metal, and Glass applications, which ensures true end-to-end inspection on any line.

Omnivision 4 with Intellect: Revolutionizing Empty Bottle Inspection

The FILTEC Omnivision 4 with Intellect is a game-changer in empty bottle inspection. It combines the advantages of existing inspection technologies with FILTEC's unique Intellect platform, offering exceptional inspection performance and user-friendly operation. What sets Omnivision 4 apart is its intelligent monitoring of the entire product packaging process. From inspecting container quality to providing real-time feedback throughout production, this solution empowers manufacturers with invaluable intelligence.

Key features of the Omnivision 4 include:

- Vacuum-less starwheel design: This innovative design simplifies the inspection process, ensuring smoother operations and hassle-free maintenance.

- Simplified changeover: With Omnivision 4, switching between different bottle types becomes effortless. Manufacturers can easily adapt to specific production requirements, saving valuable time and resources.

- LINESCAN Outer Sidewall inspection technology: Offering four times the resolution of previous versions, this cutting-edge inspection technology guarantees comprehensive 360° coverage of the bottle surface without any direct contact.

Tethered Cap Inspection: Enhancing PET Bottle Quality and Filler Management

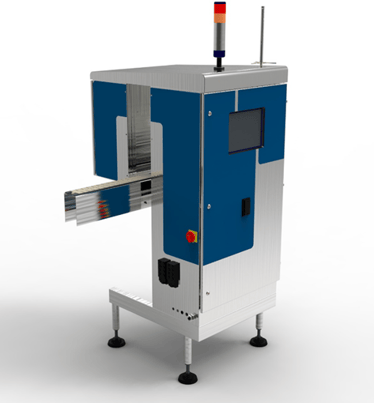

FILTEC introduces an advanced camera-based inspector for PET bottles - the Tethered Cap Inspection system. This system goes beyond conventional methods by providing unmatched precision in detecting low-fill, high-fill, and typical cap defects. It offers detailed statistical data on filler valve and capper head performance, enabling operators to identify and address problematic areas. Additionally, the system includes a sampling feature for quality control and can be seamlessly integrated with a Scada Server through an Ethernet Interface using the OMAC/Weihenstephan protocol. Label inspection is another feature that ensures complete quality assurance.

INTELLECT PRESSURE: Advanced 3D Scanning Module for Accurate Inspection

The INTELLECT PRESSURE system is a highly intelligent and reliable solution for inspecting pressure, vacuum, and leak detection in containers. It uses advanced 3D scanning technology to provide true and consistent inspection results. With three-dimensional views of the container, false rejects due to alignment issues are prevented. The self-correcting algorithms ensure accurate inspections even with variances. Furthermore, multiple adaptive algorithms evaluate 3D image data in real-time, achieving impressive inspection speeds of over 1,200 CPM.

To learn more about FILTEC and our innovative solutions, please visit our website at www.filtec.com.

(888) 434-5832

(888) 434-5832