When Oravida Waters Ltd. began its search for a full bottle inspection solution, they selected FILTEC inspection solutions for their bottling line based on the following criteria:

- Small Footprint

- Line Speed

- User-friendly Interface

About the Customer

Oravida Waters Ltd. is New Zealand’s leading contract bottling facility for premium quality artesian mineral water. Based out of the Bay of Plenty, they are responsible for the inspection of bottled still and carbonated water, in a range of packaging formats including PET, glass, and bag-in-box, for the local New Zealand market and for export. The water originates in Antarctica where gale-force winds convert the ice crystals into water vapor carried by jet-stream winds to New Zealand – Aotearoa, “the land of the long white cloud”. These water-laden clouds release this water as rain onto the Bay of Plenty region where it takes 50 years to slowly seep through layers of ancient volcanic rock, allowing the water to naturally purify itself. This natural filtration process purifies every precious drop of water, while the rock infuses the water with the perfect amount of minerals in every bottle. Oravida Waters Ltd. offers consumers superior water quality from this multi-award-winning aquifer; allowing it to be enjoyed for any occasion.

Small Footprint

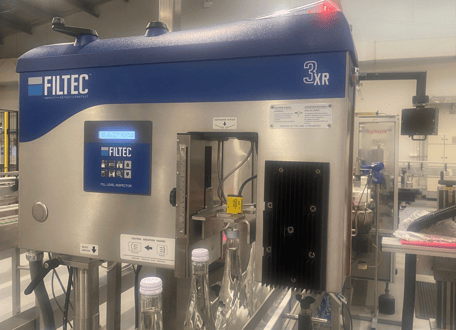

As a copacker, Oravida Waters Ltd. needs to be as flexible as possible so that it can continue to offer the largest variety of products to its customers. When it was time to select an inspection solution that would work with all varying bottle sizes, they selected FILTEC’s Fill Level 3XR inspection platform. Oravida Waters Ltd.'s main bottling line runs at a speed of up to 120 bottles per minute, filling glass and PET bottles from 300ml-1.5L at any given time. FILTEC’s Fill Level 3XR solution allows for them to easily detect underfill, overfill, and fill level as well as cap detection. FILTEC is also able to work alongside their existing capabilities seamlessly.

“Our line constraints are short and compact so the 3XR is perfect for our line. The 3XR has an overall small footprint in terms of where it stands and how it stands,” explains Phillip Davies, Plant Engineer at Oravida Waters Ltd. FILTEC’s Fill Level 3XR solution uses X-Ray technology for a range of height detection such as underfill, overfill and fill level various shapes, sizes, and types of containers. The solution ensures precise filling in various shapes, sizes, and types of containers. Fill levels are inspected and controlled even when the content is not visible from the outside of the container.

Speed of the line

Oravida Waters Ltd. has been able to get the most precise inspection on their line because they are able to control the speed of the machine to fit their line needs. “We asked that any equipment we purchased [be able to accommodate] 240 bottles per minute. Although we do not run our line at the full 240 bottles per minute, we know it’s more than capable of handling that speed,” says Davies.

User-friendly Interface

One of the questions that Oravida Waters Ltd. was looking to be answered when looking for a full bottle solution was, “Can our operators easily navigate this machine?” Thankfully the answer was yes! FILTEC’s user-friendly operator station allows anyone working on the line to adjust the solution easily.

“We wanted something that was user-friendly so that our operators can adjust things like SKU and height with ease,” states Davies.

Oravida Waters Ltd.’s goal is to provide perfectly pure water just as nature intended it to be, and with the help of FILTEC solutions, they can achieve that goal.

Learn more about all of Oravida Waters Ltd. services at: https://www.waterbottling.co.nz/

(888) 434-5832

(888) 434-5832