Schilling Cider and FILTEC - A Partnership in Quality Assurance

About Schilling Cider

Schilling Hard Cider selected FILTEC inspection solutions for their canning line based on the following requirements:

Quality through Innovation

Schilling Hard Cider is a business started by two friends in 2012 but has deep roots in a family name that started selling spices back in the 1800’s. Today, co-founders, Colin Schilling and Mark Kornei produce bold, flavor forward ciders.

"Constant innovation is the key to great products. It also helps create happy customers. We want to make sure that we’re taking advantage of the freshest and highest quality ingredients as well as creating products that are a little off-the-beaten-path." says Mark Kornei.

Schilling Cider packs its ciders in cans to ensure better product protection, convenience and low environmental impact.

The Schilling Cider can line began as a greenfield project over two years ago. The design called for a throughput of between 800-1000 cans per minute (CPM) with tunnel pasteurization, Velcorin, and multiple forms of secondary packaging. The canning line was commissioned at the end of 2019. The company also has the ability to handle multiple streams of blending and running still or carbonated beverages.

The Drive for Quality and Performance

Mark Kornei headed up the new canning line project, dealing with a number of vendors with the objective of producing a high-efficiency operation and consistent product delivery. Following diligent field research, Mark selected FILTEC for the new line’s inspection solutions.

"We needed solutions capable of driving quality and productivity using the latest technologies," explains Kornei, "while also being reliable and easy to maintain. FILTEC's solutions met all of our requirements."

High on the must-have list was the ability to ensure that every can is full and seamed correctly following the pasteurizer. Consequently, the new line called for two FILTEC 3G Inspection fill level modules and rejecters before and after the pasteurizer. This inspection strategy prevents improperly filled cans from entering the pasteurizer. The system is setup such that if three out of a row of five cans are rejected the filler is stopped. The post-pasteurizer fill inspection further guarantees that can seams are sound prior to the packaging area.

High on the must-have list was the ability to ensure that every can is full and seamed correctly following the pasteurizer. Consequently, the new line called for two FILTEC 3G Inspection fill level modules and rejecters before and after the pasteurizer. This inspection strategy prevents improperly filled cans from entering the pasteurizer. The system is setup such that if three out of a row of five cans are rejected the filler is stopped. The post-pasteurizer fill inspection further guarantees that can seams are sound prior to the packaging area.

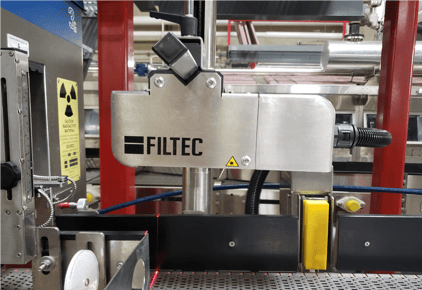

The FILTEC Auratec inspection module was added after the seamer to ensure proper pressurization of still beverages. Auratec is an optical device comprised of non-contact, high-resolution, adaptive Vision inspection and laser profiling technology. It precisely measures the external surface topography of each can to ensure that they meet its internal pressure requirements. Its inspection capabilities include vacuum and pressure sealing for aluminum, ring-pull, slimline and conventional cans.

The FILTEC Auratec inspection module was added after the seamer to ensure proper pressurization of still beverages. Auratec is an optical device comprised of non-contact, high-resolution, adaptive Vision inspection and laser profiling technology. It precisely measures the external surface topography of each can to ensure that they meet its internal pressure requirements. Its inspection capabilities include vacuum and pressure sealing for aluminum, ring-pull, slimline and conventional cans.

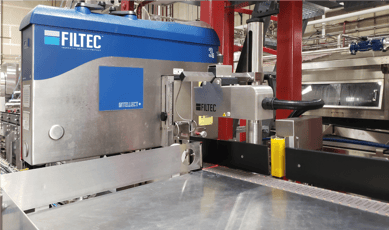

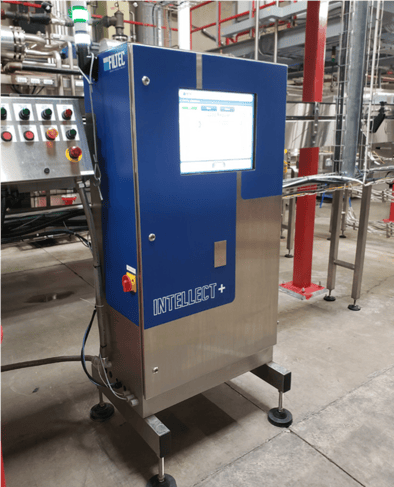

The FILTEC solutions are integrated with the INTELLECT intelligent inspection platform. INTELLECT is a configurable, flexible, state-of-the-art adaptive platform that synchronizes data from each inspection module. Its high-accuracy encoders and optical sensors inspect every can in detail as it proceeds down the line. Data from the modules is analyzed and checked against threshold reject limits according to the applicable quality standards entered by the operators. The cans are then tracked and either continue or are removed from the line if necessary. Following inspection, a quality summary is available for each can.

Additional smart INTELLECT inspection modules can be connected at any time, ensuring the future of Shilling Cider's line remains innovative and data-driven.

Learn more about Shilling Hard Cider at: https://www.schillingcider.com

About Schilling Cider

When Oravida Waters Ltd. began its search for a full bottle inspection solution, they selected...

About the Customer

Call us today! (888) 434-5832

Request a Quote (888) 434-5832

(888) 434-5832